Continuous Rod Gripper Blocks

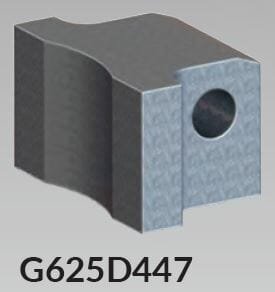

Continuous Rod Gripper Blocks have changed many times in the last 20 years. Originally made from High-Grade Aluminum (both our square G625D247 and T block G625D447) they were designed with the understanding that the blocks are the wearable component in Continuous Rod Injectors. With the main focus being the integrity of the continuous rod installation. Downhole conditions are harsh, any damage to the continuous rod during the installation or removal of that rod is absolutely unacceptable.

The 2-piece Continuous Rod Gripper block design allows our wishbone carriers to be hardened and withstand the harsh environments seen at the wellhead and allows the blocks (the part that comes in contact with the rod) to be made of a softer material. If the block portion was designed as the same material as the carrier the block would be much harder than any of continuous rod that exists in the industry today. We have opted for a block that lands between 19-23 HRc, while the carriers are 50 HRc or greater. Across the industry continuous rod manufacturer’s rod ranges from 28-36 HRc.

Block Hardness

In the early days of X-celerator Units (X-300 and X-400 injectors) high strength aluminum was the material of choice. The Aluminum Gripper Blocks have a hardness of approximately 7 HRc or less. The primary reason for this was to wear out the gripper block before marking the rod. Since those early days, we have continued to innovate and we believe we’ve been able to reach a good balance for both the Operator and the Service provider. Operators require the highest quality installation (rod that is unmarked as it’s installed). The Service Provider needs a product that has the lifespan to ensure they’re maximizing the useful life of their tools.

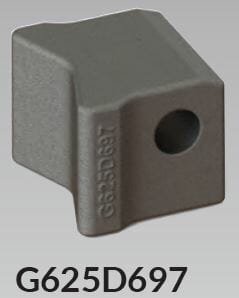

Our solution is the cast steel gripper block (the G625D697), with an increased lifespan and a higher friction coefficient than the Aluminum blocks. The Cast Steel Blocks have in the field operating for over 4 years. Maintaining the highest quality continuous rod installations in the industry at a reasonable cost to both the operator and the service provider.