Attract ESG Investment OFS

Attract ESG Investment to your OFS company, reduce emissions, reduce risk, increase your efficiency, and increase your bottom line. Directional wells have put a strain on the Well Completions Industry over the past 10 years. Well Profiles are getting deeper, more complex, and more deviated. Our industry always rises to the occasion, as such we’ve looked for existing solutions, like the adaptation of the conventional snubbing jack (an HCU or Hydraulic Completions Unit) to provide well service, completion, workover operations. Not only are we focused on the internal challenges of our industry, but we now face a lack of external investment if we cannot demonstrate that our industry is focusing on ESG solutions (Environmental-Social-Corporate Governance).

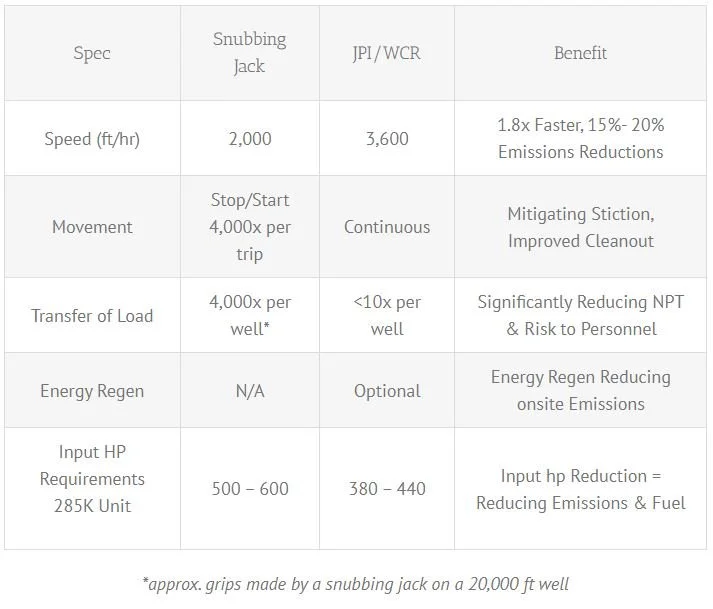

While the rest of the drilling and coil industry has undertaken large innovation advancements the Snubbing Jack has changed little in the last 30 years. Stationary and traveling slips limit the amount of movement into or out of a wellbore in a process that heavily relies on operator training and skill. There are few highly trained, and highly skilled people in the industry today, and even less in 10 years. This highly trained personnel operate the Snubbing Jack from the “BBQ Basket” putting those operators directly in harm’s way. Moving the Jack double the length of the trip in or out is slow and inefficient. Wasting energy resetting the slips over and over and opening up the margin of error to a manually operated process.

By reviewing the operation from fresh eyes we can see that by increasing the speed of individual components of the system we are still constrained by the inherent old technology. By starting from a fresh piece of design paper we are able to focus on solving these challenges while incorporating today’s ESG investment goals for our oil and gas industry. Here at Automated Rig, we have taken a “Theories of Constraint” philosophy to solve these issues.

The theory of constraints (TOC) is a management paradigm that views any manageable system as being limited in achieving more of its goals by a very small number of constraints. There is always at least one constraint, and TOC uses a focusing process to identify the constraint and restructure the rest of the organization around it. TOC adopts the common idiom “a chain is no stronger than its weakest link”

The Jointed Pipe Injector allows the oil and gas industry to attract ESG investment to our OFS company’s focused on well completions, well service, well intervention, and more by removing the surface equipment constraints and focusing on the wellbore constraints. The Jointed Pipe Injector moves pipe/tubing in one direction In-Hole or Out-Hole (continuously) and removes the need for an operator to stand in the “BBQ Basket”. The injector never loses grip, continuously moves in one direction, and automates the repetitive manual tasks that are completed by personnel these days. This keeps your operators safely positioned in a control cab away from the wellbore and provide them with the necessary data to make informed decisions from that safe distance.

This solution is ready for the field now, the Jointed Pipe Injector integrated into the Well Completions Rig. The reach of jointed pipe, the speed of coil tubing, and the control of high spec drilling wrapped up into a well completions solution that reduces your environmental footprint in the field.